Cumulative Damage Model for Progress Stress Profiles

ALTA_Reference_Examples_Banner.png

|

ALTA_Reference_Examples |

Compares the results of a cumulative damage model for a ramp stress test.

Reference Case

The data set is from the table on page 232 in the book Accelerated Testing: Statistical Models, Test Plans, and Data Analysis by Dr. Nelson, John Wiley & Sons, 1990. The model of Eqn. (3.10) is used and the results are given in Section 3 of Table 3.2 on page 511.

Data

An accelerated test employed a pair of parallel disk electrodes immersed in insulating oil. The voltage V across the pair was increased linearly with time t at a specified rate, and then the voltage at oil breakdown was recorded. Since V = Rt (R is the ramp rate), the time to breakdown can be recorded. The breakdown time is also affected by the two electrode areas A. Three voltage linear rates and two electrode areas are used. The six stress profiles are:

| Voltage Ramp Rate (Volts/sec) | Area (Sq. Inch) |

|---|---|

| 10 | 1 |

| 100 | 1 |

| 1000 | 1 |

| 10 | 9 |

| 100 | 9 |

| 1000 | 9 |

The following table shows the failure data for an area of 1 square inch.

| Time to Failure | Voltage Ramp Rate | Time to Failure | Voltage Ramp Rate | Time to Failure | Voltage Ramp Rate |

|---|---|---|---|---|---|

| 41 | 10 | 46 | 100 | 55 | 1000 |

| 43 | 10 | 50 | 100 | 57 | 1000 |

| 42 | 10 | 39 | 100 | 59 | 1000 |

| 43 | 10 | 36 | 100 | 57 | 1000 |

| 44 | 10 | 47 | 100 | 55 | 1000 |

| 40 | 10 | 55 | 100 | 60 | 1000 |

| 38 | 10 | 49 | 100 | 53 | 1000 |

| 47 | 10 | 58 | 100 | 51 | 1000 |

| 43 | 10 | 50 | 100 | 57 | 1000 |

| 45 | 10 | 48 | 100 | 54 | 1000 |

| 38 | 10 | 53 | 100 | 57 | 1000 |

| 44 | 10 | 54 | 100 | 64 | 1000 |

| 49 | 10 | 55 | 100 | 53 | 1000 |

| 42 | 10 | 37 | 100 | 63 | 1000 |

| 42 | 10 | 53 | 100 | 51 | 1000 |

| 51 | 10 | 52 | 100 | 62 | 1000 |

| 39 | 10 | 53 | 100 | 62 | 1000 |

| 34 | 10 | 50 | 100 | 56 | 1000 |

| 41 | 10 | 52 | 100 | 62 | 1000 |

| 41 | 10 | 50 | 100 | 57 | 1000 |

| 35 | 10 | 45 | 100 | 41 | 1000 |

| 44 | 10 | 48 | 100 | 41 | 1000 |

| 46 | 10 | 53 | 100 | 51 | 1000 |

| 39 | 10 | 50 | 100 | 58 | 1000 |

| 41 | 10 | 43 | 100 | 59 | 1000 |

| 40 | 10 | 50 | 100 | 60 | 1000 |

| 52 | 10 | 42 | 100 | 58 | 1000 |

| 40 | 10 | 45 | 100 | 55 | 1000 |

| 35 | 10 | 47 | 100 | 59 | 1000 |

| 40 | 10 | 34 | 100 | 63 | 1000 |

| 39 | 10 | 46 | 100 | 63 | 1000 |

| 46 | 10 | 42 | 100 | 53 | 1000 |

| 47 | 10 | 46 | 100 | 63 | 1000 |

| 44 | 10 | 46 | 100 | 61 | 1000 |

| 41 | 10 | 52 | 100 | 59 | 1000 |

| 46 | 10 | 47 | 100 | 53 | 1000 |

| 46 | 10 | 53 | 100 | 60 | 1000 |

| 42 | 10 | 52 | 100 | 58 | 1000 |

| 45 | 10 | 45 | 100 | 62 | 1000 |

| 42 | 10 | 47 | 100 | 56 | 1000 |

| 44 | 10 | 43 | 100 | 69 | 1000 |

| 41 | 10 | 45 | 100 | 65 | 1000 |

| 44 | 10 | 54 | 100 | 51 | 1000 |

| 38 | 10 | 51 | 100 | 56 | 1000 |

| 36 | 10 | 46 | 100 | 55 | 1000 |

| 44 | 10 | 55 | 100 | 57 | 1000 |

| 50 | 10 | 44 | 100 | 54 | 1000 |

| 47 | 10 | 49 | 100 | 63 | 1000 |

| 49 | 10 | 49 | 100 | 65 | 1000 |

| 46 | 10 | 53 | 100 | 65 | 1000 |

| 34 | 10 | 53 | 100 | 56 | 1000 |

| 47 | 10 | 54 | 100 | 54 | 1000 |

| 49 | 10 | 53 | 100 | 65 | 1000 |

| 43 | 10 | 53 | 100 | 60 | 1000 |

| 43 | 10 | 51 | 100 | 60 | 1000 |

| 48 | 10 | 48 | 100 | 64 | 1000 |

| 34 | 10 | 49 | 100 | 60 | 1000 |

| 38 | 10 | 52 | 100 | 54 | 1000 |

| 47 | 10 | 45 | 100 | 57 | 1000 |

| 35 | 10 | 49 | 100 | 61 | 1000 |

The following table shows the failure data for an area of 9 square inch.

| Time to Failure | Voltage Ramp Rate | Time to Failure | Voltage Ramp Rate | Time to Failure | Voltage Ramp Rate |

|---|---|---|---|---|---|

| 33 | 10 | 43 | 100 | 50 | 1000 |

| 37 | 10 | 42 | 100 | 53 | 1000 |

| 38 | 10 | 45 | 100 | 50 | 1000 |

| 38 | 10 | 48 | 100 | 49 | 1000 |

| 38 | 10 | 38 | 100 | 53 | 1000 |

| 37 | 10 | 44 | 100 | 51 | 1000 |

| 27 | 10 | 37 | 100 | 47 | 1000 |

| 42 | 10 | 44 | 100 | 44 | 1000 |

| 39 | 10 | 43 | 100 | 53 | 1000 |

| 38 | 10 | 42 | 100 | 42 | 1000 |

| 42 | 10 | 43 | 100 | 49 | 1000 |

| 32 | 10 | 49 | 100 | 46 | 1000 |

| 42 | 10 | 44 | 100 | 50 | 1000 |

| 40 | 10 | 45 | 100 | 38 | 1000 |

| 32 | 10 | 50 | 100 | 48 | 1000 |

| 38 | 10 | 44 | 100 | 43 | 1000 |

| 36 | 10 | 44 | 100 | 52 | 1000 |

| 42 | 10 | 45 | 100 | 53 | 1000 |

| 20 | 10 | 41 | 100 | 52 | 1000 |

| 37 | 10 | 48 | 100 | 48 | 1000 |

| 43 | 10 | 45 | 100 | 45 | 1000 |

| 40 | 10 | 48 | 100 | 53 | 1000 |

| 38 | 10 | 43 | 100 | 52 | 1000 |

| 43 | 10 | 49 | 100 | 50 | 1000 |

| 39 | 10 | 50 | 100 | 55 | 1000 |

| 41 | 10 | 45 | 100 | 50 | 1000 |

| 35 | 10 | 45 | 100 | 43 | 1000 |

| 41 | 10 | 46 | 100 | 52 | 1000 |

| 40 | 10 | 47 | 100 | 50 | 1000 |

| 32 | 10 | 42 | 100 | 54 | 1000 |

| 38 | 10 | 47 | 100 | 51 | 1000 |

| 40 | 10 | 48 | 100 | 40 | 1000 |

| 37 | 10 | 47 | 100 | 52 | 1000 |

| 29 | 10 | 48 | 100 | 53 | 1000 |

| 31 | 10 | 39 | 100 | 47 | 1000 |

| 41 | 10 | 49 | 100 | 45 | 1000 |

| 38 | 10 | 44 | 100 | 53 | 1000 |

| 36 | 10 | 47 | 100 | 47 | 1000 |

| 35 | 10 | 34 | 100 | 54 | 1000 |

| 40 | 10 | 41 | 100 | 50 | 1000 |

| 37 | 10 | 45 | 100 | 32 | 1000 |

| 41 | 10 | 48 | 100 | 48 | 1000 |

| 36 | 10 | 44 | 100 | 53 | 1000 |

| 39 | 10 | 47 | 100 | 52 | 1000 |

| 43 | 10 | 45 | 100 | 45 | 1000 |

| 42 | 10 | 50 | 100 | 48 | 1000 |

| 43 | 10 | 40 | 100 | 48 | 1000 |

| 43 | 10 | 47 | 100 | 51 | 1000 |

| 41 | 10 | 47 | 100 | 53 | 1000 |

| 44 | 10 | 43 | 100 | 48 | 1000 |

| 37 | 10 | 49 | 100 | 54 | 1000 |

| 43 | 10 | 45 | 100 | 51 | 1000 |

| 38 | 10 | 45 | 100 | 50 | 1000 |

| 40 | 10 | 45 | 100 | 54 | 1000 |

| 40 | 10 | 47 | 100 | 35 | 1000 |

| 38 | 10 | 39 | 100 | 56 | 1000 |

| 33 | 10 | 44 | 100 | 51 | 1000 |

| 40 | 10 | 37 | 100 | 48 | 1000 |

| 35 | 10 | 47 | 100 | 48 | 1000 |

| 41 | 10 | 48 | 100 | 46 | 1000 |

Result

The following life stress relationship and Weibull distribution are used to analyze the data. At a constant stress V, the [math]\displaystyle{ \eta\,\! }[/math] is:

- [math]\displaystyle{ ln\left(\eta(V, A)\right) = \alpha_{0}+\alpha_{1}ln(V)+\alpha_{2}ln(A)\,\! }[/math]

where V is the voltage and A is the area.

The reliability function at time t and stress V is:

- [math]\displaystyle{ R(t,V,A) = e^{-\left(\frac{t}{\eta(V,A)} \right)^\beta}\,\! }[/math]

When stress is varying with time, the reliability at time t is given as follows:

- [math]\displaystyle{ R(t,V,A) = e^{-\left(\int_{0}^{t}\frac{1}{\eta(x,A)}dx\right)^\beta} }[/math]

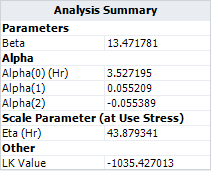

In the book, the following results are provided:

- The ML solution for the parameters are given in Section 3 of Table 3.2 on page 511: [math]\displaystyle{ 1/\beta\,\! }[/math] = 0.07856677 ([math]\displaystyle{ \beta\,\! }[/math]=12.728027) , [math]\displaystyle{ \alpha_{0}\,\! }[/math] = 3.673202 , [math]\displaystyle{ \alpha_{1} = \,\! }[/math]0.05843506 , and [math]\displaystyle{ \alpha_{2}=\,\! }[/math]-0.058626.

- The maximum log likelihood is -1035.4269.

Results in ALTA

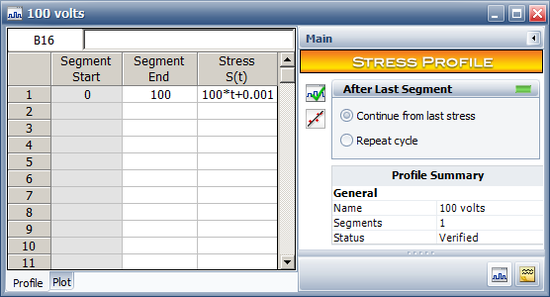

First, we create a stress profile in ALTA for each of three ramp rates: 10 volts/sec, 100 volts/sec and 1,000 volts/sec. For example, the following picture shows the stress profile for the 100 volts/sec ramp rate.

Note that the log transformation is used for voltage. At time 0, the voltage value will be 0 if the profile is defined as V(t) = 100*t; therefore, to define this stress profile, we add a small number (i.e., 0.001) to the voltage function.

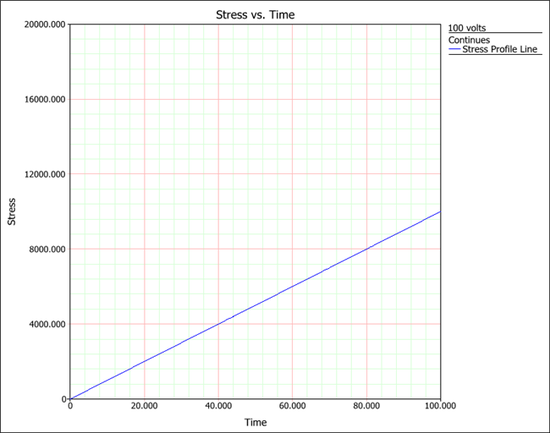

The following picture shows the plot for this stress profile.

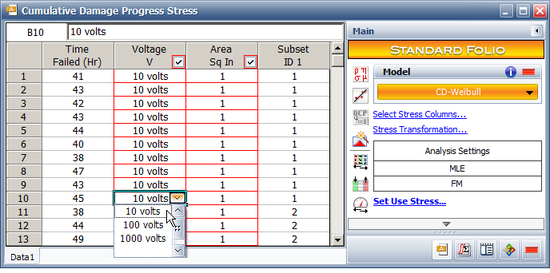

The next step is to enter the failure data into an ALTA standard folio and then use the stress profiles to define the stress values, as shown next.

The log transformation is used for both stresses. The results in ALTA show that the calculated parameters are close to the results in the book, while the log likelihood value (LK Value) is exactly the same as the value given in the book, as shown next.

Validate the Likelihood Value Calculation in ALTA

For the ML solution given in the book, the log likelihood value is -1035.4269.