Difference Detection Matrix Example: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 11: | Line 11: | ||

[[Image: Detection Matrix Example B10 Intervals.png|thumb|center|400px]] | [[Image: Detection Matrix Example B10 Intervals.png|thumb|center|400px]] | ||

[[Image: Detection Matrix Example Parameter Estimator.png|thumb|center|400px]] | |||

[[Image: Detection Matrix Example Expected Failure Tiime.png|thumb|center|400px]] | |||

[[Image: Detection Matrix Example Std Folio Data.png.png|thumb|center|400px]] | |||

[[Image: Detection Matrix Example B10 QCP.png.png|thumb|center|400px]] | |||

Revision as of 19:07, 24 February 2012

Test Design Using Life Difference Detection Matrix

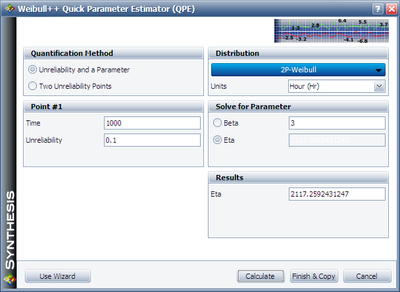

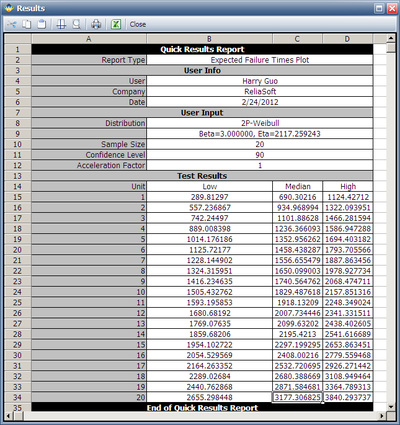

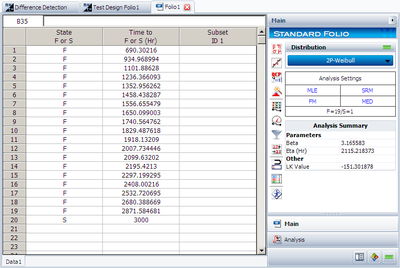

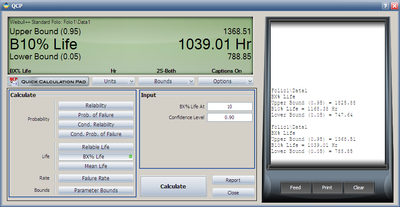

Assume there are two design options for a new product. Engineers need to design a test to compare the reliability perfomance of these two options. Both designs are assumed following Weibull distribution. For Design 1, its shape parameter

Solution

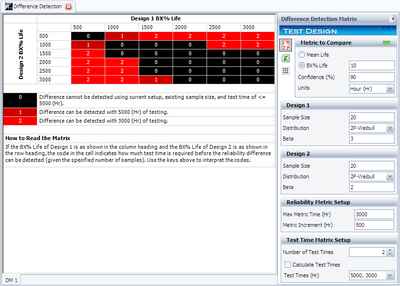

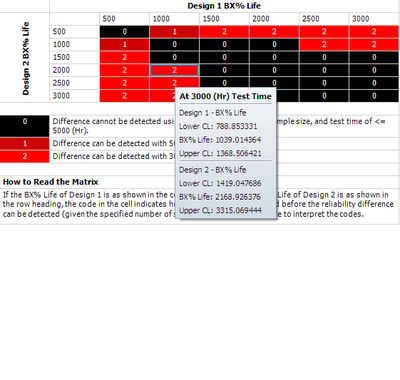

Initially, the sample size for each design is set to 20. Two test durations 3,000 and 5,000 also were chosen. Based on these settings and the assumptions on the failure time distributions, the following Difference Detection Matrix is obtained.