Template:Example: Stress-Strength Analysis with Parameter Uncertainty: Difference between revisions

Lisa Hacker (talk | contribs) No edit summary |

Lisa Hacker (talk | contribs) No edit summary |

||

| Line 1: | Line 1: | ||

'''Stress-Strength Analysis with Parameter Uncertainty''' | '''Stress-Strength Analysis with Parameter Uncertainty''' | ||

Assume we are going to use stress-strength analysis to estimate the reliability of a component used in a vehicle. The stress is the usage mileage distribution and the strength is the failure mileage distribution of the component. The warranty is 1 year or 15,000 miles, whichever is earlier. The table below gives the mileage distribution per year. | Assume we are going to use stress-strength analysis to estimate the reliability of a component used in a vehicle. The stress is the usage mileage distribution and the strength is the failure mileage distribution of the component. The warranty is 1 year or 15,000 miles, whichever is earlier. The table below gives the mileage distribution per year. | ||

{| | {| cellspacing="0" border="1" style="margin: 1em auto;" class="wikitable" | ||

|- | |- | ||

| | | align="center" style="background: none repeat scroll 0% 0% rgb(240, 240, 240);" colspan="2" | '''Stress: Usage Mileage Distribution'''<br> | ||

|- | |- | ||

| | | align="center" | 10096 | ||

| align="center" | 12405 | |||

|- | |- | ||

| | | align="center" | 10469 | ||

| align="center" | 12527 | |||

|- | |- | ||

| | | align="center" | 10955 | ||

| align="center" | 12536 | |||

|- | |- | ||

| | | align="center" | 11183 | ||

| align="center" | 12595 | |||

|- | |- | ||

| | | align="center" | 11391 | ||

| align="center" | 12657 | |||

|- | |- | ||

| | | align="center" | 11486 | ||

| align="center" | 13777 | |||

|- | |- | ||

| | | align="center" | 11534 | ||

| align="center" | 13862 | |||

|- | |- | ||

| | | align="center" | 11919 | ||

| align="center" | 13971 | |||

|- | |- | ||

| | | align="center" | 12105 | ||

| align="center" | 14032 | |||

|- | |- | ||

| | | align="center" | 12141 | ||

| align="center" | 14138 | |||

|} | |} | ||

<br> The next table gives the strength distribution or the failure mileage distribution. | |||

{| cellspacing="0" border="1" style="margin: 1em auto;" class="wikitable" | |||

{| | |||

|- | |- | ||

| | | align="center" style="background: none repeat scroll 0% 0% rgb(240, 240, 240);" colspan="2" | '''Strength: Failure Mileage Distribution'''<br> | ||

|- | |- | ||

| | | align="center" | 13507 | ||

| align="center" | 16125 | |||

|- | |- | ||

| | | align="center" | 13793 | ||

| align="center" | 16320 | |||

|- | |- | ||

| | | align="center" | 13943 | ||

| align="center" | 16327 | |||

|- | |- | ||

| | | align="center" | 14017 | ||

| align="center" | 16349 | |||

|- | |- | ||

| | | align="center" | 14147 | ||

| align="center" | 16406 | |||

|- | |- | ||

| | | align="center" | 14351 | ||

| align="center" | 16501 | |||

|- | |- | ||

| | | align="center" | 14376 | ||

| align="center" | 16611 | |||

|- | |- | ||

| | | align="center" | 14595 | ||

| align="center" | 16625 | |||

|- | |- | ||

| | | align="center" | 14746 | ||

| align="center" | 16670 | |||

|- | |- | ||

| | | align="center" | 14810 | ||

| align="center" | 16749 | |||

|- | |- | ||

| | | align="center" | 14940 | ||

| align="center" | 16793 | |||

|- | |- | ||

| | | align="center" | 14951 | ||

| align="center" | 16862 | |||

|- | |- | ||

| | | align="center" | 15104 | ||

| align="center" | 16930 | |||

|- | |- | ||

| | | align="center" | 15218 | ||

| align="center" | 16948 | |||

|- | |- | ||

| | | align="center" | 15303 | ||

| align="center" | 17024 | |||

|- | |- | ||

| | | align="center" | 15311 | ||

| align="center" | 17041 | |||

|- | |- | ||

| | | align="center" | 15480 | ||

| align="center" | 17263 | |||

|- | |- | ||

| | | align="center" | 15496 | ||

| align="center" | 17347 | |||

|- | |- | ||

| | | align="center" | 15522 | ||

| align="center" | 17430 | |||

|- | |- | ||

| | | align="center" | 15547 | ||

| align="center" | 17805 | |||

|- | |- | ||

| | | align="center" | 15570 | ||

| align="center" | 17884 | |||

|- | |- | ||

| | | align="center" | 15975 | ||

| align="center" | 18549 | |||

|- | |- | ||

| | | align="center" | 16003 | ||

| align="center" | 18575 | |||

|- | |- | ||

| | | align="center" | 16018 | ||

| align="center" | 18813 | |||

|- | |- | ||

| | | align="center" | 16052 | ||

| align="center" | 18944 | |||

|} | |} | ||

The goal is to estimate the reliability of the component within the warranty period (1 year/15,000 miles). | The goal is to estimate the reliability of the component within the warranty period (1 year/15,000 miles). | ||

'''Solution''' | <br> '''Solution''' | ||

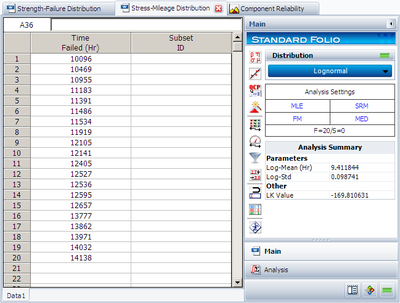

First, we need to estimate the stress and strength distributions using the above data. The estimated stress distribution is: | First, we need to estimate the stress and strength distributions using the above data. The estimated stress distribution is: | ||

[[Image: Stress-Strength Example 1 Stress-Distribution.png|thumb|center|400px]] | [[Image:Stress-Strength Example 1 Stress-Distribution.png|thumb|center|400px]] | ||

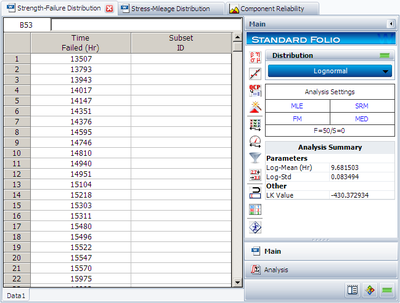

The estimated strength distribution is: | The estimated strength distribution is: | ||

[[Image: Stress-Strength Example 1 Strength-Distribution.png|thumb|center|400px]] | [[Image:Stress-Strength Example 1 Strength-Distribution.png|thumb|center|400px]] | ||

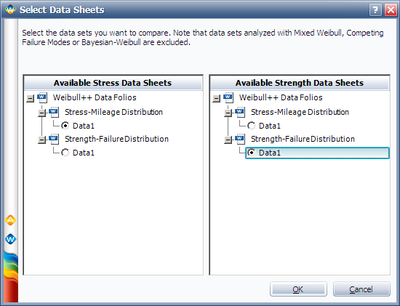

Add one '''Stress-Strength''' folio and choose the stress and strength distributions: | Add one '''Stress-Strength''' folio and choose the stress and strength distributions: | ||

[[Image: Stress-Strength Example 1 Choose Folios.png|thumb|center|400px]] | [[Image:Stress-Strength Example 1 Choose Folios.png|thumb|center|400px]] | ||

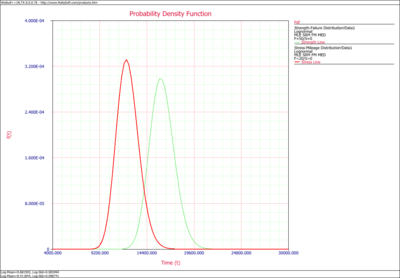

The stress-strength tool shows the '' | The stress-strength tool shows the ''pdfs'' of the selected data folios. The ''pdf'' curves are shown next: | ||

[[Image: Stress-Strength Example 1 pdf curve.png|thumb|center|400px]] | [[Image:Stress-Strength Example 1 pdf curve.png|thumb|center|400px]] | ||

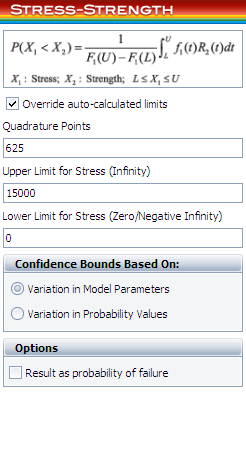

Since the warranty is 1 year/15,000 miles, all the vehicles with mileage larger than 15,000 should not be considered in the calculation. Therefore, the conditional stress distribution conditioning on the mileage less than 15,000 should be used. This is done by using the following settings in the | Since the warranty is 1 year/15,000 miles, all the vehicles with mileage larger than 15,000 should not be considered in the calculation. Therefore, the conditional stress distribution conditioning on the mileage less than 15,000 should be used. This is done by using the following settings in the tool: | ||

[[Image: Stress-Strength Example 1 Calculation Settings.png|thumb|center|400px]] | [[Image:Stress-Strength Example 1 Calculation Settings.png|thumb|center|400px]] | ||

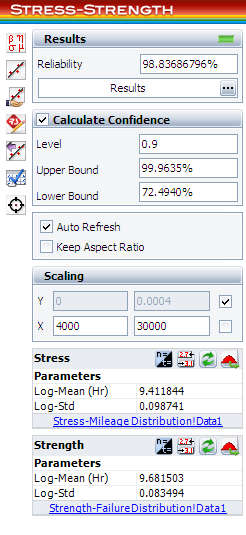

The calculated results are | The calculated results are: | ||

[[Image: Stress-Strength Example 1 Calculation Results.png|thumb|center|400px]] | [[Image:Stress-Strength Example 1 Calculation Results.png|thumb|center|400px]] | ||

The estimated reliability for vehicles less than 15,000 miles per year is 98.84%. The associated confidence bounds are estimated from the variance of the distribution parameters. With larger samples for the stress and strength data, the width of the bounds will be narrower. | The estimated reliability for vehicles less than 15,000 miles per year is 98.84%. The associated confidence bounds are estimated from the variance of the distribution parameters. With larger samples for the stress and strength data, the width of the bounds will be narrower. | ||

Revision as of 01:41, 30 March 2012

Stress-Strength Analysis with Parameter Uncertainty

Assume we are going to use stress-strength analysis to estimate the reliability of a component used in a vehicle. The stress is the usage mileage distribution and the strength is the failure mileage distribution of the component. The warranty is 1 year or 15,000 miles, whichever is earlier. The table below gives the mileage distribution per year.

| Stress: Usage Mileage Distribution | |

| 10096 | 12405 |

| 10469 | 12527 |

| 10955 | 12536 |

| 11183 | 12595 |

| 11391 | 12657 |

| 11486 | 13777 |

| 11534 | 13862 |

| 11919 | 13971 |

| 12105 | 14032 |

| 12141 | 14138 |

The next table gives the strength distribution or the failure mileage distribution.

| Strength: Failure Mileage Distribution | |

| 13507 | 16125 |

| 13793 | 16320 |

| 13943 | 16327 |

| 14017 | 16349 |

| 14147 | 16406 |

| 14351 | 16501 |

| 14376 | 16611 |

| 14595 | 16625 |

| 14746 | 16670 |

| 14810 | 16749 |

| 14940 | 16793 |

| 14951 | 16862 |

| 15104 | 16930 |

| 15218 | 16948 |

| 15303 | 17024 |

| 15311 | 17041 |

| 15480 | 17263 |

| 15496 | 17347 |

| 15522 | 17430 |

| 15547 | 17805 |

| 15570 | 17884 |

| 15975 | 18549 |

| 16003 | 18575 |

| 16018 | 18813 |

| 16052 | 18944 |

The goal is to estimate the reliability of the component within the warranty period (1 year/15,000 miles).

Solution

First, we need to estimate the stress and strength distributions using the above data. The estimated stress distribution is:

The estimated strength distribution is:

Add one Stress-Strength folio and choose the stress and strength distributions:

The stress-strength tool shows the pdfs of the selected data folios. The pdf curves are shown next:

Since the warranty is 1 year/15,000 miles, all the vehicles with mileage larger than 15,000 should not be considered in the calculation. Therefore, the conditional stress distribution conditioning on the mileage less than 15,000 should be used. This is done by using the following settings in the tool:

The calculated results are:

The estimated reliability for vehicles less than 15,000 miles per year is 98.84%. The associated confidence bounds are estimated from the variance of the distribution parameters. With larger samples for the stress and strength data, the width of the bounds will be narrower.