Logistic Model Examples: Difference between revisions

Kate Racaza (talk | contribs) (Created page with '<noinclude>{{Banner RGA Examples}}{{Navigation box}} ''This example appears in the Reliability Growth and Repairable System Analysis Reference book''. </noinclude> …') |

Lisa Hacker (talk | contribs) No edit summary |

||

| (3 intermediate revisions by one other user not shown) | |||

| Line 1: | Line 1: | ||

<noinclude>{{Banner RGA Examples}}{{Navigation box}} | <noinclude>{{Banner RGA Examples}}{{Navigation box}} | ||

'' | ''These examples appear in the [https://help.reliasoft.com/reference/reliability_growth_and_repairable_system_analysis Reliability growth reference]''. | ||

</noinclude> | </noinclude> | ||

==Parameter Estimation: Reliability Data== | ==Parameter Estimation== | ||

===Example 1: Reliability Data=== | |||

{{:Reliability_Data_-_Logistic_Model}} | {{:Reliability_Data_-_Logistic_Model}} | ||

== | ===Example 2: Sequential Success/Failure Data=== | ||

{{:Sequential_Data_-_Logistic_Model}} | {{:Sequential_Data_-_Logistic_Model}} | ||

== | ===Example 3: Grouped per Configuration Data=== | ||

{{:Grouped_per_Configuration_Data_-_Logistic_Model}} | {{:Grouped_per_Configuration_Data_-_Logistic_Model}} | ||

===Confidence Bounds Example=== | |||

{{:Logistic_Confidence_Bounds_Example}} | |||

==Missile Launch Test Example== | |||

{{:Logistic_Model_-_Missile_Launch_Test_Example|Logistic Model}} | |||

===Missile Launch Test with Modes=== | |||

{{:Sequential_Data_with_Failure_Modes_-_Logistic_Model|Logistic Model}} | |||

==Automobile Transmission Example== | |||

{{:Logistic_Model_-_Auto_Transmission_Example|Logistic Model}} | |||

Latest revision as of 20:36, 18 September 2023

New format available! This reference is now available in a new format that offers faster page load, improved display for calculations and images and more targeted search.

As of January 2024, this Reliawiki page will not continue to be updated. Please update all links and bookmarks to the latest references at RGA examples and RGA reference examples.

These examples appear in the Reliability growth reference.

Parameter Estimation

Example 1: Reliability Data

Using the reliability growth data given in the table below, do the following:

- Find a Gompertz curve that represents the data and plot it with the raw data.

- Find a Logistic reliability growth curve that represents the data and plot it with the raw data.

| Time, months | Raw Data Reliability (%) | Gompertz Reliability (%) | Logistic Reliablity (%) |

|---|---|---|---|

| 0 | 31.00 | 24.85 | 22.73 |

| 1 | 35.50 | 38.48 | 38.14 |

| 2 | 49.30 | 51.95 | 56.37 |

| 3 | 70.10 | 63.82 | 73.02 |

| 4 | 83.00 | 73.49 | 85.01 |

| 5 | 92.20 | 80.95 | 92.24 |

| 6 | 96.40 | 86.51 | 96.14 |

| 7 | 98.60 | 90.54 | 98.12 |

| 8 | 99.00 | 93.41 | 99.09 |

Solution

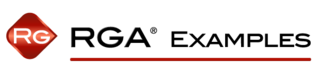

- The figure below shows the entered data and the estimated parameters using the standard Gompertz model.

Therefore:

- [math]\displaystyle{ \begin{align} & \widehat{a}= & 0.9999 \\ & \widehat{b}= & 0.2485 \\ & \widehat{c}= & 0.6858 \end{align}\,\! }[/math]

- [math]\displaystyle{ R=(0.9999){{(0.2485)}^{{{0.6858}^{T}}}}\,\! }[/math]

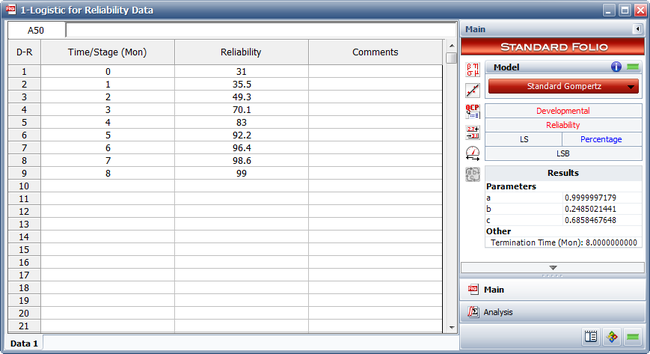

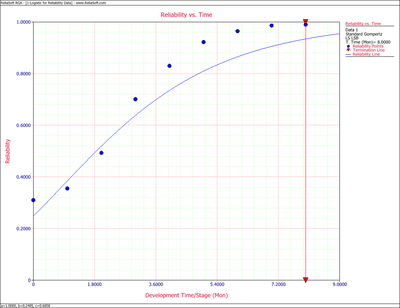

The values of the predicted reliabilities are plotted in the figure below.

Notice how the standard Gompertz model is not really capable of handling the S-shaped characteristics of this data.

- The least squares estimators of the Logistic growth curve parameters are given by Crow [9]:

where:

- [math]\displaystyle{ \begin{align} {{{\hat{b}}}_{1}}= & \frac{\underset{i=0}{\overset{N-1}{\mathop{\sum }}}\,{{T}_{i}}{{Y}_{i}}-N\cdot \bar{T}\cdot \bar{Y}}{\underset{i=0}{\overset{N-1}{\mathop{\sum }}}\,T_{i}^{2}-N\cdot {{{\bar{T}}}^{2}}} \\ \\ {{{\hat{b}}}_{0}}= & \bar{Y}-{{{\hat{b}}}_{1}}\bar{T} \\ \\ {{Y}_{i}}= & \ln \left( \frac{1}{{{R}_{i}}}-1 \right) \\ \\ \bar{Y}= & \frac{1}{N}\underset{i=0}{\overset{N-1}{\mathop \sum }}\,{{Y}_{i}} \end{align}\,\! }[/math]

- [math]\displaystyle{ \begin{align} \overline{Y}&=\frac{1}{9}\sum_{i=0}^{8}ln\left (\frac{1}{R_{i}}-1 \right ) \\ &= -1.7355 \\ \\ \overline{T}&=\frac{1}{9}\sum_{i=0}^{8}T_{i} = 4 \\ \sum_{i=0}^{8}T_{i}^{2} &= 204 \\ \sum_{i=0}^{8}T_{i}Y_{i} &= -106.8630 \end{align}\,\! }[/math]

- [math]\displaystyle{ \begin{align} \hat{b_{1}} &= \frac{-106.8630 - 9(4)(-1.7355)}{204-9(4)_{2}} \\ & = 0.7398 \\ \hat{b_{0}} &= -1.7355 - (-0.7398)(4)\\ &= 1.2235 \end{align}\,\! }[/math]

- [math]\displaystyle{ \begin{align} \widehat{b}= & {{e}^{1.2235}} \\ = & 3.3991 \\ \widehat{k}= & -(-0.7398) \\ = & 0.7398 \end{align}\,\! }[/math]

- [math]\displaystyle{ R=\frac{1}{1+3.3991\,{{e}^{-0.7398\,T}}}\,\! }[/math]

Example 2: Sequential Success/Failure Data

A prototype was tested under a success/failure pattern. The test consisted of 15 runs. The following table presents the data from the test. Find the Logistic model that best fits the data set, and plot it along with the reliability observed from the raw data.

| Time | Result | Observed Reliability |

|---|---|---|

| 0 | F | 0.5000 |

| 1 | F | 0.3333 |

| 2 | S | 0.5000 |

| 3 | S | 0.6000 |

| 4 | F | 0.5000 |

| 5 | S | 0.5714 |

| 6 | S | 0.6250 |

| 7 | S | 0.6667 |

| 8 | S | 0.7000 |

| 9 | F | 0.6364 |

| 10 | S | 0.6667 |

| 11 | S | 0.6923 |

| 12 | S | 0.7143 |

| 13 | S | 0.7333 |

Solution

The first run is ignored because it was a success, and the reliability at that point was 100%. This failure will be ignored throughout the analysis because it is considered that the test starts when the reliability is not equal to zero or one. The test essentially begins at time 1, and is now considered as time 0 with [math]\displaystyle{ N=14\,\! }[/math]. The observed reliability is shown in the last column of the table. Keep in mind that the observed reliability values still account for the initial suspension.

Therefore:

- [math]\displaystyle{ \begin{align} \bar{Y}= & \frac{1}{N}\underset{i=0}{\overset{N-1}{\mathop \sum }}\,{{Y}_{i}} \\ = & \frac{1}{14}\underset{i=0}{\overset{13}{\mathop \sum }}\,\ln \left( \frac{1}{{{R}_{i}}}-1 \right) \\ = & -0.43163 \end{align}\,\! }[/math]

and:

- [math]\displaystyle{ \begin{align} \bar{T}= & \frac{1}{14}\underset{i=0}{\overset{13}{\mathop \sum }}\,{{T}_{i}} \\ = & 6.5 \\ \underset{i=0}{\overset{13}{\mathop \sum }}\,T_{i}^{2}= & 819.0 \\ \underset{i=0}{\overset{13}{\mathop \sum }}\,{{T}_{i}}{{Y}_{i}}= & -61.69 \end{align}\,\! }[/math]

Now, from the least squares estimators, the values are:

- [math]\displaystyle{ \begin{align} {{{\hat{b}}}_{1}}&= \frac{\underset{i=0}{\overset{N-1}{\mathop{\sum }}}\,{{T}_{i}}{{Y}_{i}}-N\cdot \bar{T}\cdot \bar{Y}}{\underset{i=0}{\overset{N-1}{\mathop{\sum }}}\,T_{i}^{2}-N\cdot {{{\bar{T}}}^{2}}} \\ \\ &= \frac{-61.69-14 \cdot 6.5 \cdot (-.43163)}{819.0-14 \cdot 6.5^{2}} \\ &= -0.0985 \\ \\ \hat{b_{0}}&= \overline{Y} - \hat{b_{1}}\overline{T} \\ &= (-.043163)-(-0.0985) \cdot 6.5 \\ &= 0.2087 \end{align}\,\! }[/math]

Therefore:

- [math]\displaystyle{ \begin{align} \widehat{b}= & {{e}^{0.2087}} \\ = & 1.2321 \\ \widehat{k}= & -(-0.0985) \\ = & 0.0985 \end{align}\,\! }[/math]

The Logistic reliability model that best fits the data is given by:

- [math]\displaystyle{ R=\frac{1}{1+1.2321\cdot \ \,{{e}^{-0.0985T}}}\,\! }[/math]

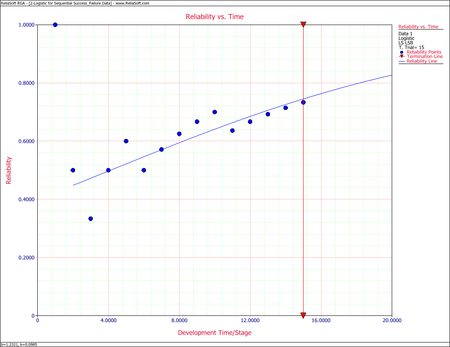

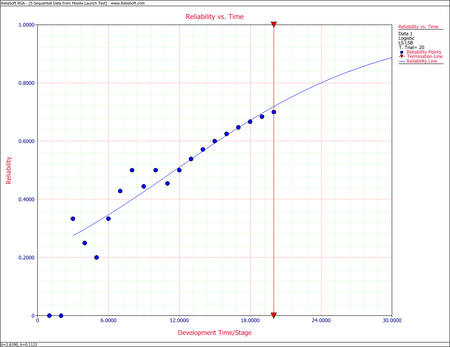

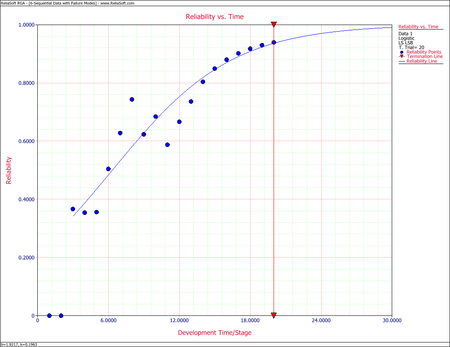

The following figure shows the Reliability vs. Time plot.

Example 3: Grouped per Configuration Data

Some equipment underwent testing in different stages. The testing may have been performed in subsequent days, weeks or months with an unequal number of units tested every day. Each group was tested and several failures occurred. The data set is given in columns 1 and 2 of the following table. Find the Logistic model that best fits the data, and plot it along with the reliability observed from the raw data.

| Number of Units | Number of Failures | [math]\displaystyle{ T_i\,\! }[/math] | Observed Reliability |

|---|---|---|---|

| 10 | 5 | 0 | 0.5000 |

| 8 | 3 | 1 | 0.6250 |

| 9 | 3 | 2 | 0.6667 |

| 9 | 2 | 3 | 0.7778 |

| 10 | 2 | 4 | 0.8000 |

| 10 | 1 | 5 | 0.9000 |

| 10 | 1 | 6 | 0.9000 |

| 10 | 1 | 7 | 0.9000 |

| 10 | 1 | 8 | 0.9000 |

Solution

The observed reliability is [math]\displaystyle{ 1-\tfrac{\#\text{ of failures}}{\#\text{ of units}}\,\! }[/math] and the last column of the table above shows the values for each group. With [math]\displaystyle{ N=9\,\! }[/math], the least square estimator [math]\displaystyle{ \overline{Y} }[/math] becomes:

- [math]\displaystyle{ \begin{align} \bar{Y}= & \frac{1}{9}\underset{i=0}{\overset{8}{\mathop \sum }}\,\ln \left( \frac{1}{{{R}_{i}}}-1 \right) \\ = & -1.4036 \end{align}\,\! }[/math]

and:

- [math]\displaystyle{ \begin{align} \bar{T}= & \frac{1}{9}\underset{i=0}{\overset{8}{\mathop \sum }}\,{{T}_{i}} \\ = & 4 \\ \underset{i=0}{\overset{8}{\mathop \sum }}\,T_{i}^{2}= & 204 \\ \underset{i=0}{\overset{8}{\mathop \sum }}\,{{T}_{i}}{{Y}_{i}}= & -68.33 \end{align}\,\! }[/math]

Now from the least squares estimators, [math]\displaystyle{ \hat{b_{i}}\,\! }[/math] and [math]\displaystyle{ \hat{b_{0}}\,\! }[/math], we have:

- [math]\displaystyle{ \begin{align} {{{\hat{b}}}_{1}}= & \frac{\underset{i=0}{\overset{8}{\mathop{\sum }}}\,{{T}_{i}}{{Y}_{i}}-N\cdot \bar{T}\cdot \bar{Y}}{\underset{i=0}{\overset{8}{\mathop{\sum }}}\,T_{i}^{2}-N\cdot {{{\bar{T}}}^{2}}} \\ = & \frac{-68.33-9\cdot 4\cdot \left( -1.4036 \right)}{204-9\cdot {{4}^{2}}} \\ = & -0.2967 \\ & \\ {{{\hat{b}}}_{0}}= & \bar{Y}-{{{\hat{b}}}_{1}}\bar{T} \\ = & \left( -1.4036 \right)-\left( -0.2967 \right)\cdot 4.0 \\ = & -0.2168 \end{align}\,\! }[/math]

Therefore:

- [math]\displaystyle{ \begin{align} \widehat{b}= & {{e}^{-0.2168}} \\ = & 0.8051 \\ \widehat{k}= & -(-0.2967) \\ = & 0.2967 \end{align}\,\! }[/math]

The Logistic reliability model that best fits the data is given by:

- [math]\displaystyle{ R=\frac{1}{1+0.8051\cdot \ \,{{e}^{-0.2967T}}}\,\! }[/math]

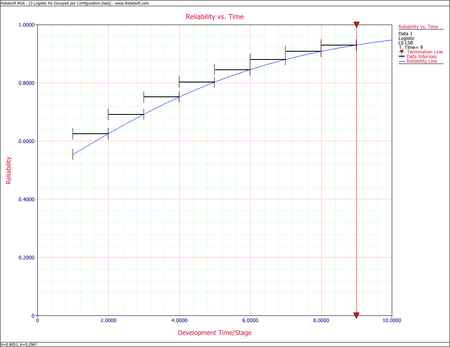

The figure below shows the Reliability vs. Time plot.

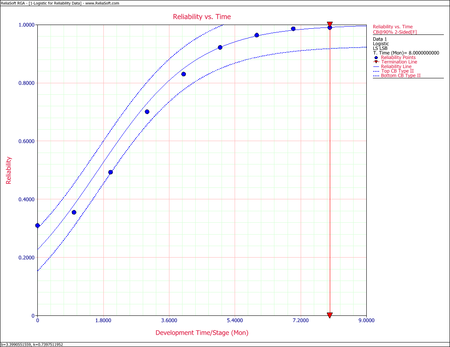

Confidence Bounds Example

For the data given above for the reliability data example, calculate the 2-sided 90% confidence bounds under the Logistic model for the following:

- The parameters [math]\displaystyle{ b\,\! }[/math] and [math]\displaystyle{ k\,\! }[/math].

- Reliability at month 5.

Solution

- The values of [math]\displaystyle{ \hat{b}\,\! }[/math] and [math]\displaystyle{ \hat{k}\,\! }[/math] that were estimated from the least squares analysis in the reliability data example are:

- [math]\displaystyle{ \begin{align} \widehat{b}= & 3.3991 \\ \widehat{\alpha }= & 0.7398 \end{align}\,\! }[/math]

- [math]\displaystyle{ \begin{align} {{b}_{lower}}= & 2.5547 \\ {{b}_{upper}}= & 4.5225 \end{align}\,\! }[/math]

- [math]\displaystyle{ \begin{align} {{k}_{lower}}= & 0.6798 \\ {{k}_{upper}}= & 0.7997 \end{align}\,\! }[/math]

- First, calculate the reliability estimation at month 5:

- [math]\displaystyle{ \begin{align} {{R}_{5}}= & \frac{1}{1+b{{e}^{-5k}}} \\ = & 0.9224 \end{align}\,\! }[/math]

- [math]\displaystyle{ \begin{align} {{[{{R}_{5}}]}_{lower}}= & 0.8493 \\ {{[{{R}_{5}}]}_{upper}}= & 0.9955 \end{align}\,\! }[/math]

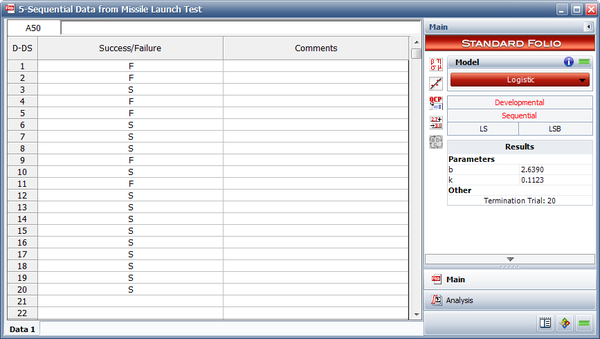

Missile Launch Test Example

The following table presents the results for a missile launch test. The test consisted of 20 attempts. If the missile launched, it was recorded as a success. If not, it was recorded as a failure. Note that, at this development stage, the test did not consider whether or not the target was destroyed.

- Find a Logistic reliability growth curve that best represents the data.

- Plot it comparatively with the raw data.

- If design changes continue to be incorporated and the testing continues, when will the reliability goal of 99.5% with a 90% confidence level be achieved?

- If design changes continue to be incorporated and the testing continues, what will be the attainable reliability at the end of the 35th launch?

| Launch Number | Result |

|---|---|

| 1 | F |

| 2 | F |

| 3 | S |

| 4 | F |

| 5 | F |

| 6 | S |

| 7 | S |

| 8 | S |

| 9 | F |

| 10 | S |

| 11 | F |

| 12 | S |

| 13 | S |

| 14 | S |

| 15 | S |

| 16 | S |

| 17 | S |

| 18 | S |

| 19 | S |

| 20 | S |

Solution

- The next figure shows the entered data and the estimated parameters.

- The next figure displays the Reliability vs. Time plot.

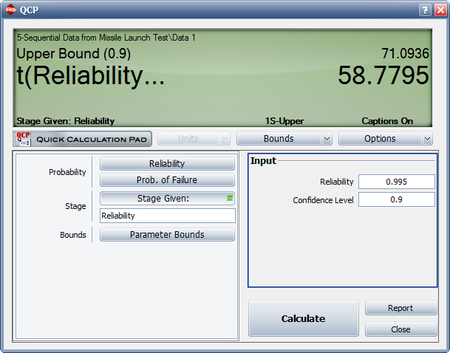

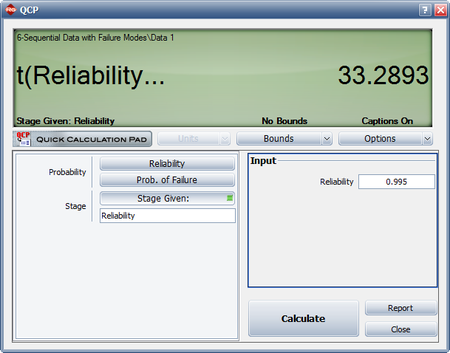

- The next figure displays the number of launches before the reliability goal of 99.5% will be achieved with a 90% confidence level.

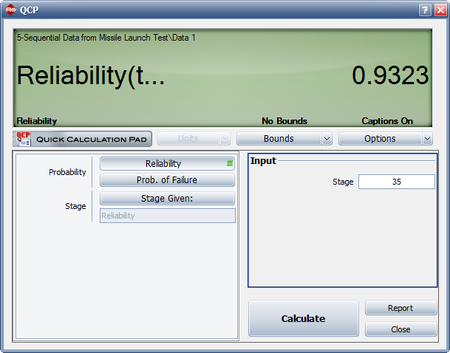

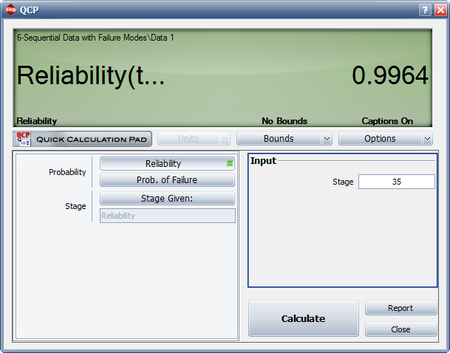

- The next figure displays the reliability achieved after the 35th launch.

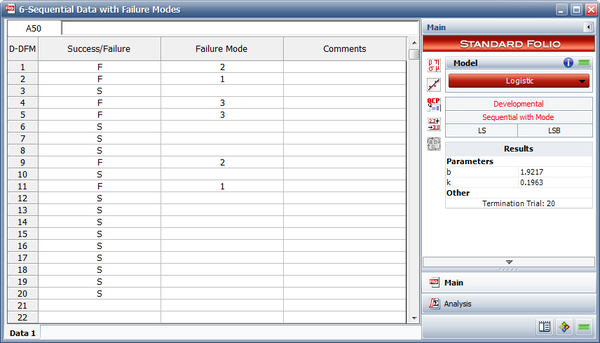

Missile Launch Test with Modes

Consider the data given in the previous example. Now suppose that the engineers assigned failure modes to each failure and that the appropriate corrective actions were taken.

The table below presents the data.

- Find the Logistic reliability growth curve that best represents the data.

- Plot it comparatively with the raw data.

- If design changes continue to be incorporated and the testing continues, when will the reliability goal of 99.50% be achieved?

- If design changes continue to be incorporated and the testing continues, what will be the attainable reliability at the end of the 35th launch?

| Launch Number | Result | Mode |

|---|---|---|

| 1 | F | 2 |

| 2 | F | 1 |

| 3 | S | |

| 4 | F | 3 |

| 5 | F | 3 |

| 6 | S | |

| 7 | S | |

| 8 | S | |

| 9 | F | 2 |

| 10 | S | |

| 11 | F | 1 |

| 12 | S | |

| 13 | S | |

| 14 | S | |

| 15 | S | |

| 16 | S | |

| 17 | S | |

| 18 | S | |

| 19 | S | |

| 20 | S |

Solution

- The next figure shows the entered data and the estimated parameters.

- The next figure displays the Reliability vs. Time plot.

- The next figure displays the number of launches before the reliability goal of 99.5% will be achieved.

- The last figure displays the reliability after the 35th launch.

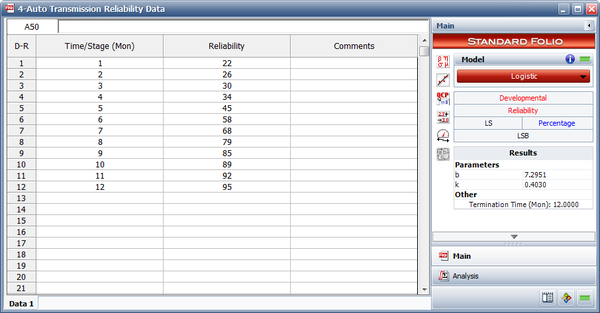

Automobile Transmission Example

The following table presents the reliabilities observed monthly for an automobile transmission that was tested for one year.

- Find a Logistic reliability growth curve that best represents the data.

- Plot it comparatively with the raw data.

- If design changes continue to be incorporated and the testing continues, when will the reliability goal of 99% be achieved?

- If design changes continue to be incorporated and the testing continues, what will be the attainable reliability at the end of January the following year?

| Month | Observed Reliability(%) |

|---|---|

| June | 22 |

| July | 26 |

| August | 30 |

| September | 34 |

| October | 45 |

| November | 58 |

| December | 68 |

| January | 79 |

| February | 85 |

| March | 89 |

| April | 92 |

| May | 95 |

Solution

- The next figure shows the entered data and the estimated parameters.

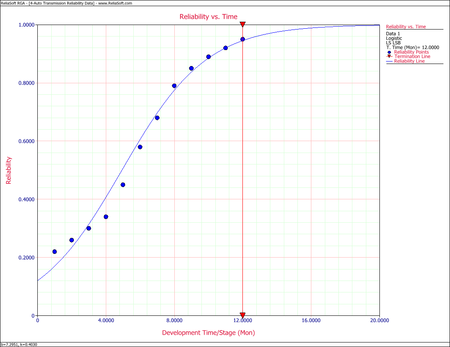

- The next figure displays the Reliability vs. Time plot.

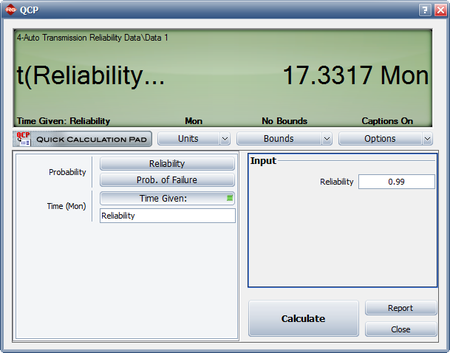

- Using the QCP, the next figure displays, in months, when the reliability goal of 99% will be achieved.

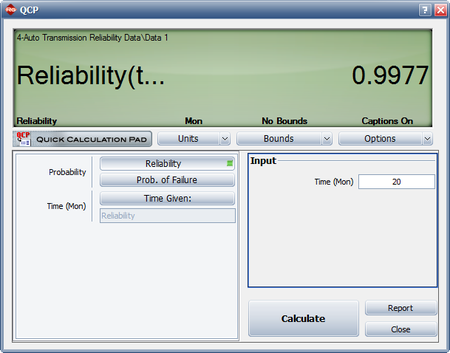

- The last figure shows the reliability at the end of January the following year (i.e., after 20 months of testing and development).