Interval Maintenance Threshold Example: Difference between revisions

No edit summary |

Lisa Hacker (talk | contribs) No edit summary |

||

| (3 intermediate revisions by one other user not shown) | |||

| Line 1: | Line 1: | ||

<noinclude>{{Banner BlockSim Examples}} | <noinclude>{{Banner BlockSim Examples}} | ||

''This example appears in the [ | ''This example appears in the [https://help.reliasoft.com/reference/system_analysis System analysis reference]''. | ||

| Line 13: | Line 13: | ||

[[Image:11.14.png|center|300px]] | [[Image:11.14.png|center|300px|link=]] | ||

[[Image:11.15.png|center|200px]] | [[Image:11.15.png|center|200px|link=]] | ||

[[Image:11t4.png|center| | [[Image:11t4.png|center|900px|link=]] | ||

| Line 25: | Line 25: | ||

[[Image:11.16.png|center| | [[Image:11.16.png|center|650px|link=]] | ||

Latest revision as of 21:02, 18 September 2023

New format available! This reference is now available in a new format that offers faster page load, improved display for calculations and images and more targeted search.

As of January 2024, this Reliawiki page will not continue to be updated. Please update all links and bookmarks to the latest references at BlockSim examples and BlockSim reference examples.

This example appears in the System analysis reference.

The Interval Maintenance Threshold property of a maintenance phase is used to specify an age interval when a maintenance task will be performed. Specifically, tasks based on system or item age intervals (fixed or dynamic) will be performed if the start of the maintenance phase is within (1-X)% of the scheduled time for the action. This helps in optimizing the resources allocated to repair the system during a maintenance phase by performing preventive maintenance actions or inspections when the system is already down in a maintenance phase. The following example demonstrates the property.

Example

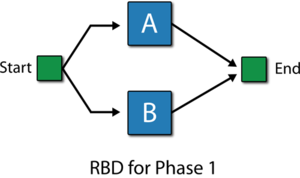

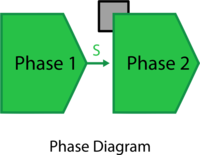

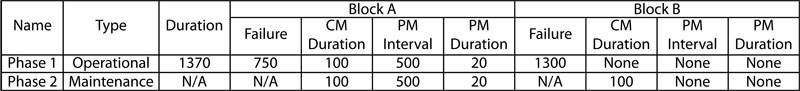

Consider a system that has two components: Block A and Block B. The system undertakes a mission that can be divided into two phases. The first phase is an operational phase with a duration of 1,370 hours, with both the components in a parallel configuration. In this phase, Block A fails every 750 hours while Block B fails every 1,300 hours. Corrective maintenance on Block A in this phase requires 100 hours to be completed. A preventive maintenance of 20 hours duration also occurs on Block A every 500 hours. No maintenance can be carried out on Block B in this phase.

The second phase of the mission is a maintenance phase. In this phase, Block A has the same maintenance actions as those in the first phase. A corrective maintenance of 100 hours duration is defined for Block B. Phase 2 also has a value of 0.70 set for the Interval Maintenance Threshold. All maintenance actions during the entire mission of the system have a type II restoration factor of 1.

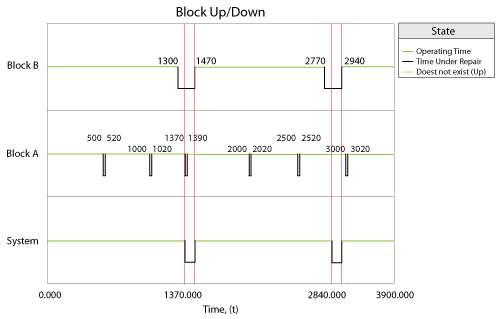

The system behavior from 0 to 3,500 hours is shown in the plot below and described next.

- Phase 1 begins at time 0 hours. The duration of this phase is 1,370 hours.

- At 500 hours, the first of the scheduled PMs for Block A begins. The duration of these maintenance tasks is 20 hours. The scheduled maintenance ends at 520 hours.

- At 1,000 hours, another PM occurs for Block A based on the set policy. This maintenance ends at 1,020 hours.

- At 1,300 hours, Block B fails after accumulating an age of 1,300 hours. A system failure does not occur because Block B is in a parallel configuration with Block A in this phase. Repairs for Block B are not defined in this phase. As a result Block B remains in a failed state.

- At 1,370 hours, phase 1 ends and phase 2 begins. Phase 2 is a maintenance phase. Block B is repairable in this phase and has a CM duration of 100 hours. As a result, repairs on Block B begin and are completed at 1,470 hours. Block A has the next PM scheduled to occur at 1,500 hours. However, phase 2 has an Interval Maintenance Threshold of 0.7 for Preventive and Inspection Policies. The time remaining to the next PM is 130 hours (1,500-1,370 = 130 hours). This remaining time over the PM policy time of 500 hours is 26%. This is within 0.3 (1-0.70 = 0.3) or 30% corresponding to the threshold value of 0.70. Thus the PM task that is to occur at 1,500 hours is carried out in the maintenance phase from 1,370 hours to 1,390 hours, while no PM occurs at 1,500 hours. All maintenance actions are completed by 1,470 hours and phase 2 ends at this time. This completes the first cycle of operation for the phase diagram.

- At 1,470 hours, phase 1 begins in the second cycle.

- At 2,000 hours, the next PM for Block A begins. This maintenance ends at 2,020 hours.

- At 2,500 hours, another PM is carried out on Block A and is completed by 2,520 hours.

- At 2,770 hours, Block B fails in the second cycle of phase 1 after accumulating an age of 1,300 hours. Since no repair is defined for the block in this phase, it remains in a failed state.

- At 2,840 hours, phase 1 completes its duration of 1,370 hours and ends. Phase 2 begins in the second cycle and the corrective maintenance, defined for a duration of 100 hours for Block B, begins. This repair action ends at 2,940 hours. For Block A, the time remaining until the next PM at 3,000 hours is 160 hours (3000-2840 = 160 hours). This remaining time over the PM policy of 500 hours is 32%. This is not within 30% corresponding to the threshold value of 0.70. Thus the PM due at 3,000 hours is not considered close enough to the beginning of the maintenance phase and is not carried out in this phase. At 2,940 hours, all maintenance actions are completed in phase 2 and phase 2 ends. This also completes the second cycle of operation for the phase diagram.

- At 2,940 hours, phase 1 begins in the third cycle.

- At 3,000 hours, the scheduled maintenance on Block A occurs. This PM ends at 3,020 hours.

- At 3,500 hours, the simulation ends.