Template:Weibull++ Event Log Folio Example: Difference between revisions

Created page with ''''Weibull++ Event Log Folio Example''' A manufacturer is tracking the failures in a product line that occurred between 8 a.m. January 1, 2004 and 5 p.m. June 24, 2005. When a f…' |

No edit summary |

||

| Line 87: | Line 87: | ||

| M-2||F||Jun-21-05||9:30:00 AM||Jun-21-05||11:00:00 AM||Hydraulic Arm||Arm|| | | M-2||F||Jun-21-05||9:30:00 AM||Jun-21-05||11:00:00 AM||Hydraulic Arm||Arm|| | ||

|} | |} | ||

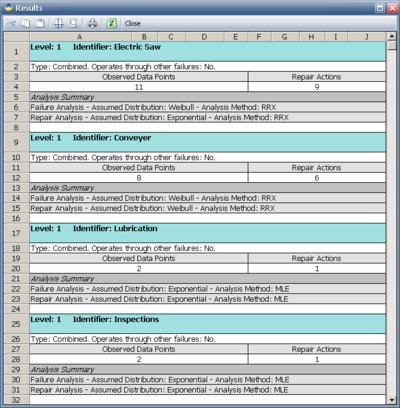

The manufacturer entered the data in the Event Log folio and decided to obtain the failure/repair distributions of the '''F''' and '''E''' occurrences jointly, which means that all general events in the data set will be treated as failures. This affects the calculation for the total uptime/downtime of the component, as well as the failure/repair distributions. The settings of the control panel is given in below: | |||

[[image:Event Log Settings.png|thumb|center|400px]] | |||

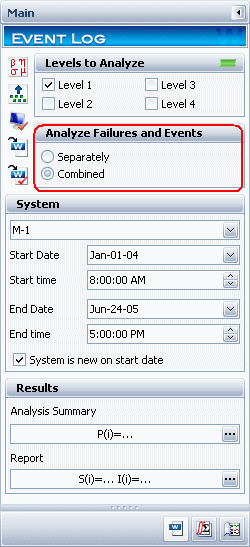

The manufacturer then calculated the results. To view the failure and repair distributions, click the '''Show Analysis Summary (...)''' button on the control panel. The Results window shows the calculated values. | |||

[[image:Event Log Results.png|thumb|center|400px]] | |||

In this example, rows 11 to 17 display the failure and repair distributions for each component due the combined events and failures. Rows 21 to 31 display the total uptime and downtime for each component due to each type of event and failure. | |||

'''Note:''' Because the manufacturer chose to combine the analysis of all events, the Results window displays the letter C in the F=Failure/E=Event column that indicates that the parameters of the distribution are a result of the combined analysis. | |||

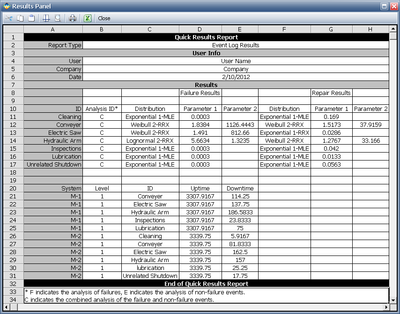

To view a report on the number of repair actions performed and other results, click the '''Show Report (...)''' button on the control panel. The Results window shows the analysis results. | |||

[[image:Event Log Report.png|thumb|center|400px]] | |||

Revision as of 17:39, 7 March 2012

Weibull++ Event Log Folio Example

A manufacturer is tracking the failures in a product line that occurred between 8 a.m. January 1, 2004 and 5 p.m. June 24, 2005. When a failure occurred in a machine, the manufacturer recorded the following information:

- The machine and parts that failed.

- The time of occurrence.

- The time the repair was completed.

The manufacturer also recorded the dates and times for the maintenance activities. The manufacturer wants to analyze each component and obtain the failure and repair distributions for all recorded events. To do so, the manufacture decides to use Weibull++’s event log folio. Event logs, or maintenance logs, store information about a piece of equipment's failures and repairs. They provide useful information that can help companies achieve their productivity goals by giving insight about the failure modes, frequency of outages, repair duration, uptime/downtime and availability of the equipment.

The manufacturer’s data includes both failures and general events. A general event represents an activity that brings the system down but is not directly relevant to the reliability of the equipment, such as preventive maintenance, routine inspections and the like. In the data sheet, failures are marked with an F and events are marked with an E. The data is given in the following Table:

| System | F/E | Data Occurred | Time Occurred | Date Restored | Time Restored | Level 1 | Level 2 | Description |

| M-1 | F | Mar-01-04 | 11:00:00 AM | Mar-05-04 | 9:00:00 AM | Electric Saw | Motor | Electrical Short |

| M-1 | F | Apr-01-04 | 2:30:00 PM | Apr-03-04 | 11:00:00 AM | Conveyer | Belt | |

| M-1 | E | May-03-04 | 9:00:00 AM | May-06-04 | 12:00:00 PM | Lubrication | Lubrication | |

| M-1 | F | Aug-03-04 | 3:30:00 PM | Aug-04-04 | 9:00:00 AM | Electric Saw | Blade | Worn |

| M-1 | E | Sep-01-04 | 4:10:00 PM | Sep-02-04 | 4:00:00 PM | Inspections | Inspections | |

| M-1 | F | Dec-01-04 | 10:00:00 AM | Dec-02-04 | 3:00:00 PM | Conveyer | Wheels | Bearings Failure |

| M-1 | F | Jan-04-05 | 12:30:00 PM | Jan-07-05 | 7:20:00 AM | Hydraulic Arm | Hydraulic Lines | |

| M-1 | F | Feb-01-05 | 4:00:00 PM | Feb-02-05 | 7:00:00 AM | Hydraulic Arm | Piston | |

| M-1 | F | Mar-07-05 | 4:15:00 PM | Mar-09-05 | 9:00:00 AM | Conveyer | Belt | Unstable |

| M-1 | F | Apr-05-05 | 4:30:00 PM | Apr-06-05 | 4:45:00 AM | Electric Saw | Blade | Crack |

| M-1 | F | May-09-05 | 3:00:00 PM | May-11-05 | 10:00:00 AM | Hydraulic Arm | Motor | Electrical Short |

| M-1 | F | May-18-05 | 2:00:00 PM | May-19-05 | 12:30:00 PM | Hydraulic Arm | Hydraulic Lines | |

| M-1 | F | Jun-02-05 | 1:00:00 PM | Jun-03-05 | 3:00:00 AM | Electric Saw | Blade | |

| M-1 | F | Jun-20-05 | 11:00:00 AM | Jun-22-05 | 2:15:00 AM | Hydraulic Arm | Hydraulic Lines | |

| M-2 | F | Feb-04-04 | 9:00:00 AM | Feb-05-04 | 9:00:00 AM | Hydraulic Arm | Piston | |

| M-2 | F | Mar-08-04 | 9:00:00 AM | Mar-09-04 | 11:00:00 AM | Electric Saw | Motor | |

| M-2 | F | Apr-05-04 | 11:00:00 AM | Apr-06-04 | 10:00:00 AM | Hydraulic Arm | Arm | |

| M-2 | F | Apr-14-04 | 2:00:00 PM | Apr-16-04 | 2:30:00 AM | Hydraulic Arm | Hydraulic Lines | |

| M-2 | F | Jun-07-04 | 1:00:00 PM | Jun-09-04 | 2:00:00 AM | Hydraulic Arm | Piston | Crack |

| M-2 | F | Jul-23-04 | 4:15:00 PM | Jul-25-04 | 3:15:00 AM | Electric Saw | Motor | Vibration |

| M-2 | F | Aug-23-04 | 3:00:00 PM | Aug-25-04 | 3:30:00 AM | Conveyer | Belt | |

| M-2 | E | Sep-27-04 | 9:20:00 AM | Sep-27-04 | 3:15:00 PM | Cleaning | Cleaning | |

| M-2 | F | Nov-08-04 | 11:00:00 AM | Nov-09-04 | 9:15:00 AM | Hydraulic Arm | Motor | |

| M-2 | F | Jan-25-05 | 10:00:00 AM | Jan-26-05 | 2:45:00 AM | Electric Saw | Blade | Loose |

| M-2 | F | Feb-03-05 | 10:00:00 AM | Feb-03-05 | 3:20:00 PM | Conveyer | Wheels | |

| M-2 | F | Mar-23-05 | 12:00:00 PM | Mar-25-05 | 4:00:00 AM | Conveyer | Belt | |

| M-2 | E | Mar-28-05 | 10:45:00 AM | Mar-29-05 | 12:00:00 PM | lubrication | lubrication | |

| M-2 | F | May-10-05 | 3:00:00 PM | May-11-05 | 10:15:00 AM | Electric Saw | Motor | Noise |

| M-2 | E | May-23-05 | 4:00:00 PM | May-24-05 | 9:45:00 AM | Unrelated Shutdown | Unrelated Shutdown | |

| M-2 | F | Jun-01-05 | 4:30:00 PM | Jun-04-05 | 10:00:00 AM | Electric Saw | Blade | |

| M-2 | F | Jun-07-05 | 3:15:00 PM | Jun-08-05 | 4:00:00 AM | Hydraulic Arm | Motor | Noise |

| M-2 | F | Jun-21-05 | 9:30:00 AM | Jun-21-05 | 11:00:00 AM | Hydraulic Arm | Arm |

The manufacturer entered the data in the Event Log folio and decided to obtain the failure/repair distributions of the F and E occurrences jointly, which means that all general events in the data set will be treated as failures. This affects the calculation for the total uptime/downtime of the component, as well as the failure/repair distributions. The settings of the control panel is given in below:

The manufacturer then calculated the results. To view the failure and repair distributions, click the Show Analysis Summary (...) button on the control panel. The Results window shows the calculated values.

In this example, rows 11 to 17 display the failure and repair distributions for each component due the combined events and failures. Rows 21 to 31 display the total uptime and downtime for each component due to each type of event and failure.

Note: Because the manufacturer chose to combine the analysis of all events, the Results window displays the letter C in the F=Failure/E=Event column that indicates that the parameters of the distribution are a result of the combined analysis.

To view a report on the number of repair actions performed and other results, click the Show Report (...) button on the control panel. The Results window shows the analysis results.